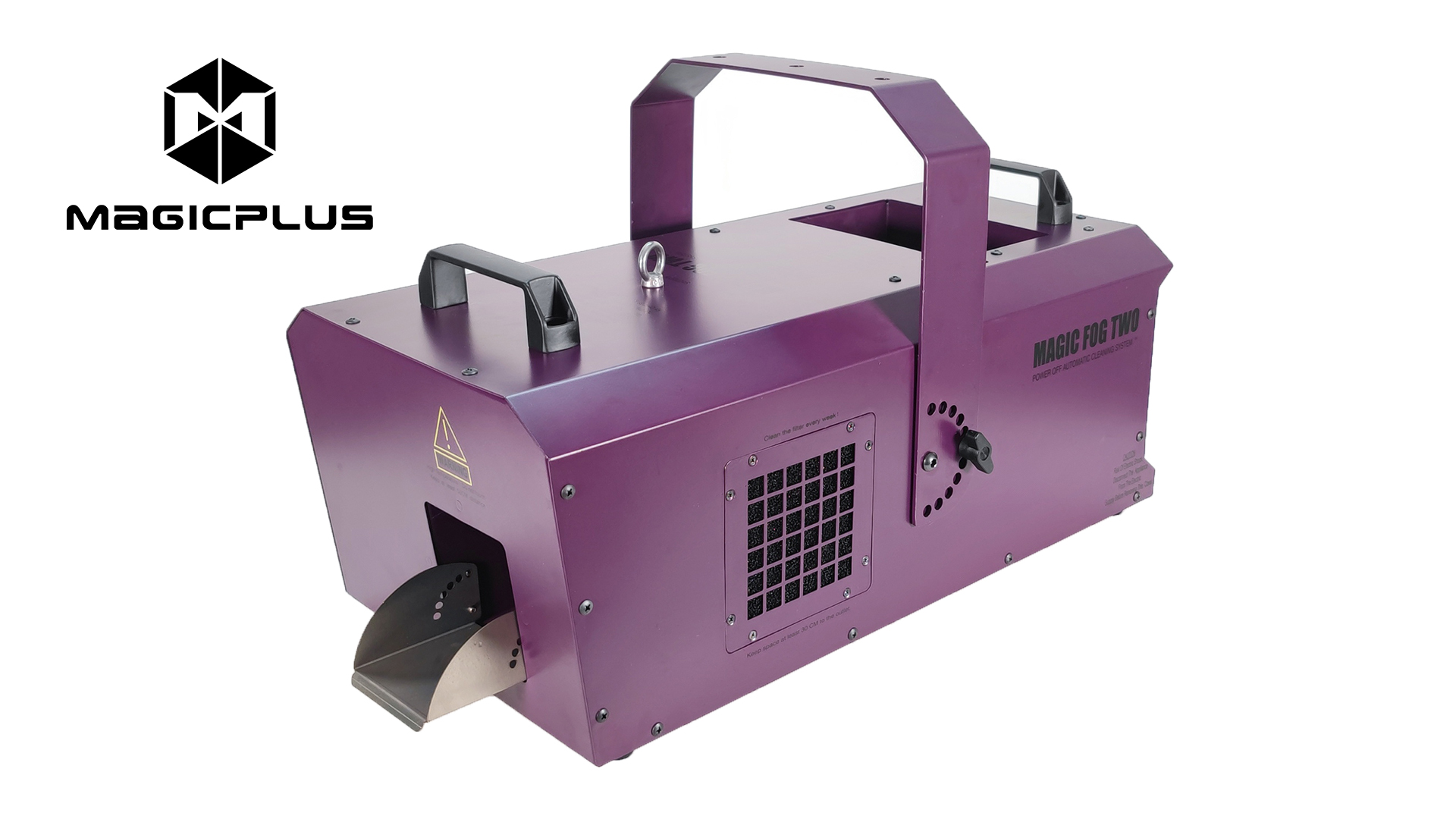

Design features

Magic fog two light, shadow and particle smoke output device, 1 ordinary fog machine, 6-8 sets

Extremely low fuel consumption. Under the condition of 1bar, the maximum fuel consumption per hour of smoke spray mode is about 60ml! Make the total operation time of a barrel of 3L fog oil up to 50 hours!!!

In the club, according to the business hours, the maximum smoke volume is 8 hours per day, and the use time of each barrel of fog oil is 6.25 days. The consumption of fog oil is 5 barrels per month (the maximum smoke is limited to 50%); The fuel consumption is basically the same as that of Canada MDG atmosphere55ml/h.

The maximum oil volume is set at 100%, and the oil consumption is 110ml/h. One machine is equivalent to two Canadian MDG aerosol fog machines. The service time of each barrel of fog oil is about 2.5 days, equivalent to 8.8 barrels of fog oil consumption per month.

The maximum oil volume is set at 150%, and the oil consumption is 165ml/h. One machine is equivalent to three sets of Canadian MDG atmospheres. The service time of each barrel of fog oil is about 2.27273 days, equivalent to 13.2 barrels of fog oil consumption per month.

Magic fog two fog machine is also second to none in terms of gas consumption and energy saving. Under the closed-loop pressure of 1bar, the gas consumption per hour is about 0.025kg.

1. with the latest design concept, carbon dioxide or ammonia are used to mix the new and special fog oil evenly. Through the innovative and complex pneumatic pipeline and oil circuit combined with the specially customized high-power heater, the output smoke is white and lasting, and stays in the air for a long time. These 0.5-0.7 micron smoke particles make the stage lighting effect more layered under the background and refraction of the light.

2. the original power off automatic cleaningsystem power off automatic cleaningsystem uses an advanced ultra-low consumption booster battery management circuit. After an unexpected power failure or shutdown, the internal power supply system will be started immediately. After the power failure is stopped, the residual smoke oil and dirt of the heating module will be cleaned, and the cold will not be blocked forever.

3. the high-power turbine fan is ingeniously implanted into the machine, and the smoke can be evenly and quickly released to all corners without an external fan.

4. dual oil pump switching operation is adopted. Under extreme service conditions, when oil pump a or B fails, it can be quickly switched to another standby oil pump through the switch behind the main engine.

5. it innovatively adopts the external pressure reduction technology, without the use of high-pressure gas pipe to connect the machine. It is more convenient to use the ordinary 6*4 transparent gas pipe for purchase, and the cost of long-distance gas transmission pipeline is lower and safer to use.

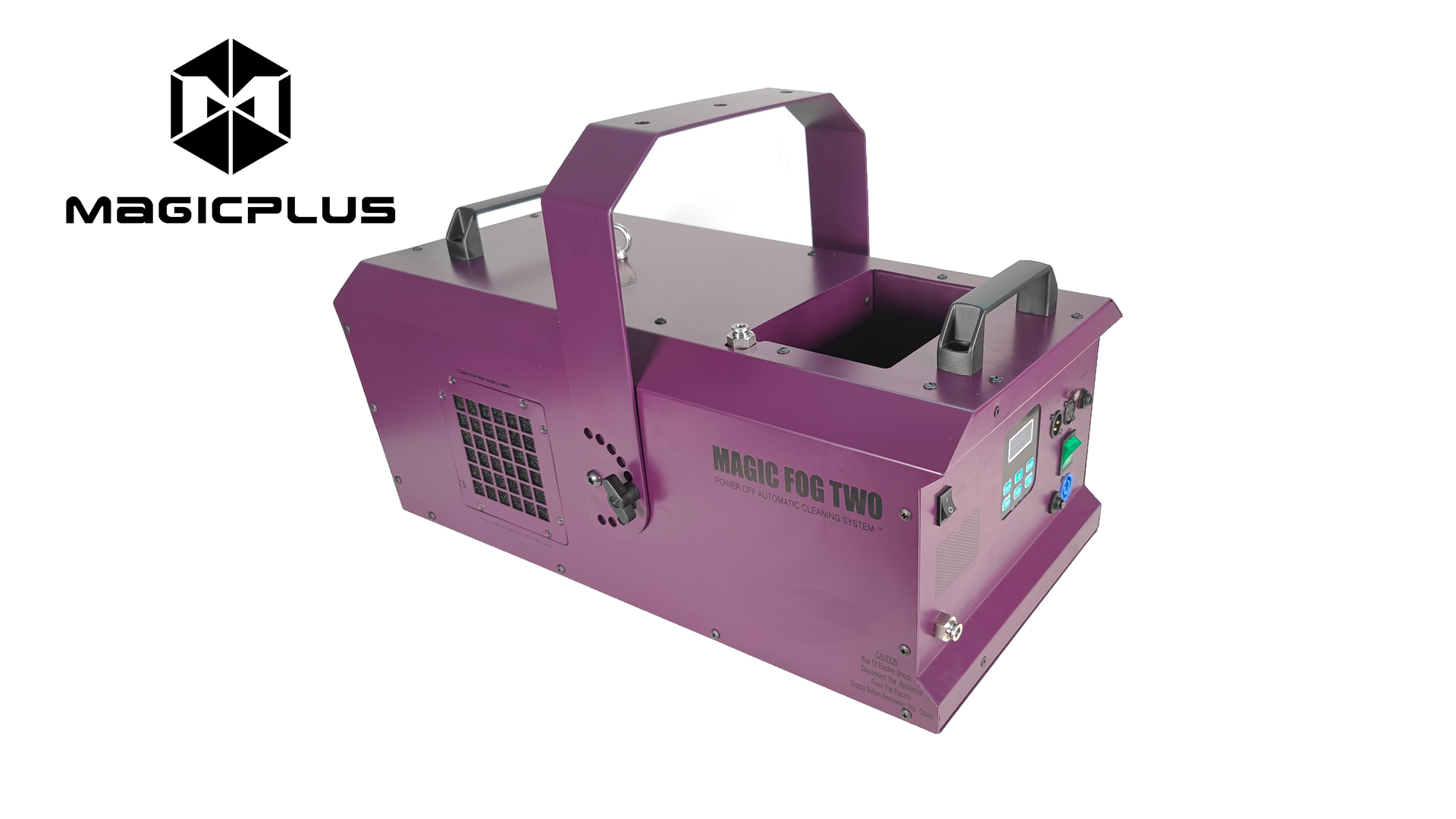

6. the two-stage pressure relief valve is adopted to protect the pipeline and expensive equipment due to out of control pressure caused by the failure of the pressure reducer.

7. the advanced pressure sensing system monitors the pressure of the gas circuit in real time. When the pressure drops to the lowest pressure of the system, the machine will automatically stop working, close the solenoid valves of the gas circuit and oil circuit, and prompt the user to replace the gas cylinder in the display area.

8. the technology of 316 BA stainless steel seamless pipe is used for the detection of cooked pipe, and the surface of high durability pipe is smooth without residue.

9. the high-power 1650W imported heater is adopted to reduce the heating time by several times, and the heating can be completed in 30 seconds: the linear temperature compensation technology is adopted, with different smoke volume differential temperature ratio, lower standby temperature and lower power consumption. The 1650 heating power enables the heating temperature of the smoke machine to be quickly compensated, and 100% of the smoke oil is completely atomized. Even under the maximum smoke spraying state, the smoke is still very dry and low-temperature, without oil injection, and more environmentally friendly and healthy; And there will be no odor due to out of control temperature.

10. the newly customized oil pump and control technology enable the machine to smoothly and continuously emit smoke even at the minimum smoke volume;

9. it supports wireless remote control and has stronger adaptability;

11. "multiple safety monitoring modes, different component damage displays different fault codes, making maintenance more convenient and fast: in addition to the electronic temperature control heater, mechanical temperature protection is added to prevent continuous high-temperature heating caused by mainboard damage: the main engine cancels the safety tube and adopts the recoverable compound overload protector, which is safer to use and easier to maintain.

12. built in multi-functional operation control: with built-in time control, manual smoke control and continuous smoke control. With digital LCD display, the function is more powerful, the operation is more simple, convenient and humanized: DMX-512 signal control, a total of 2 channels;

Specification parameters

| Model | MAGIC FOG TWO |

| Voltage | AC220~240V 50/60Hz |

| Current limiting protection | Fuse free switch(NFB 10A) |

| Power | 1800W |

| Preheating time | 1min |

| Maximum continuous smoking time | Always |

| Smoke output | 35000cuft/min |

| Tank volume | 3L |

Guangzhou magic Technology Co., Ltd. All Rights Reserved

Address: No. 17, Lane 7, congguili lane, Panyu Avenue, Donghuan street, Panyu District, Guangzhou, Guangdong